Pre-press preparation is the most important stage in the production before the material is ready to go to press.

Here is where you find how to properly prepare your files.

How to prepare your files – click here.

Files are elaborated in the Kodak InSite Prepress Portal system, where files are sent, corrected and accepted online.

The prepress studio is fitted with:

- Platesetter CTP Kodak Magnus 800 Quantum

- Plate processor Kodak mercury HD

- Laser printer Canon C700i Epson 4800 with software for colour management and the ISO certificate for colour concordance

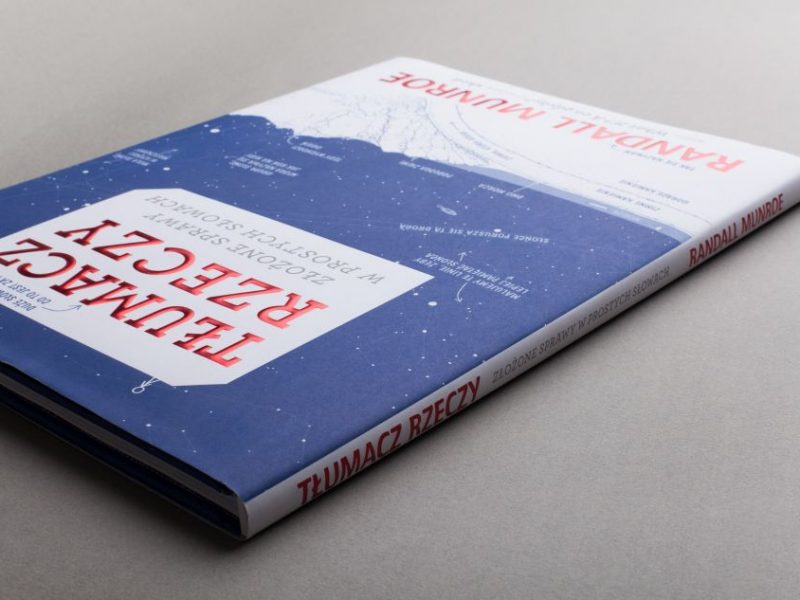

OZGraf S.A has extensive and modern machinery, allowing for the highest print quality. Printwork information is transmitted from the prepress studio directly to the printing machines via a state-of-the-art CIP3 system. Printing and the ink units are controlled in Heidelberg machines using a colour measurement system called ImageControl.

OZGraf S.A has extensive and modern machinery, allowing for the highest print quality. Printwork information is transmitted from the prepress studio directly to the printing machines via a state-of-the-art CIP3 system. Printing and the ink units are controlled in Heidelberg machines using a colour measurement system called ImageControl.

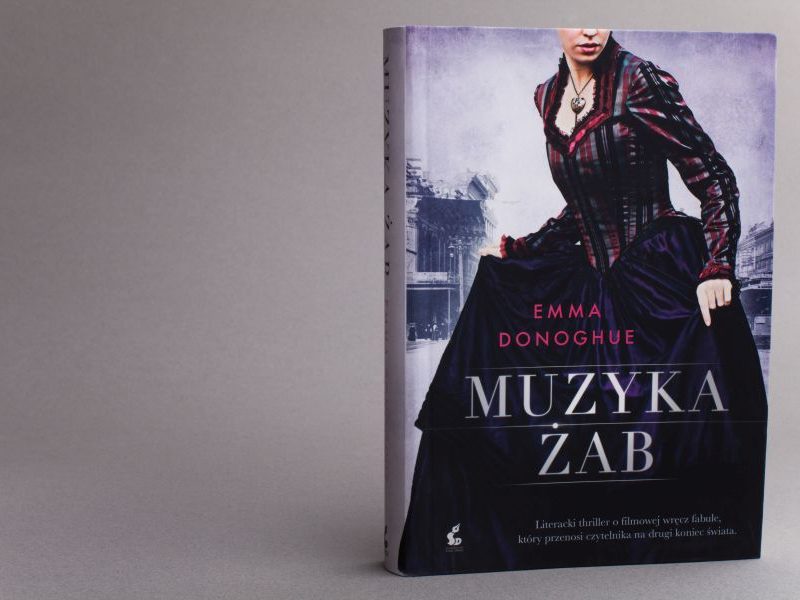

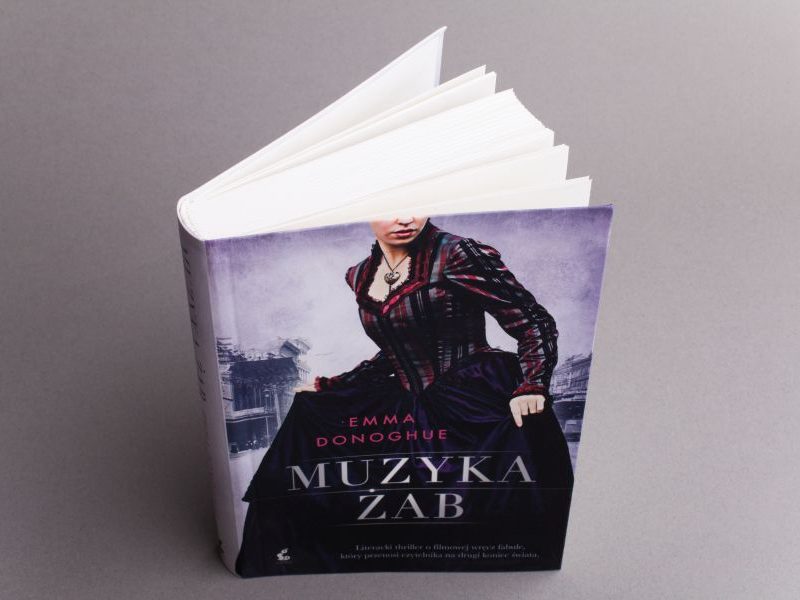

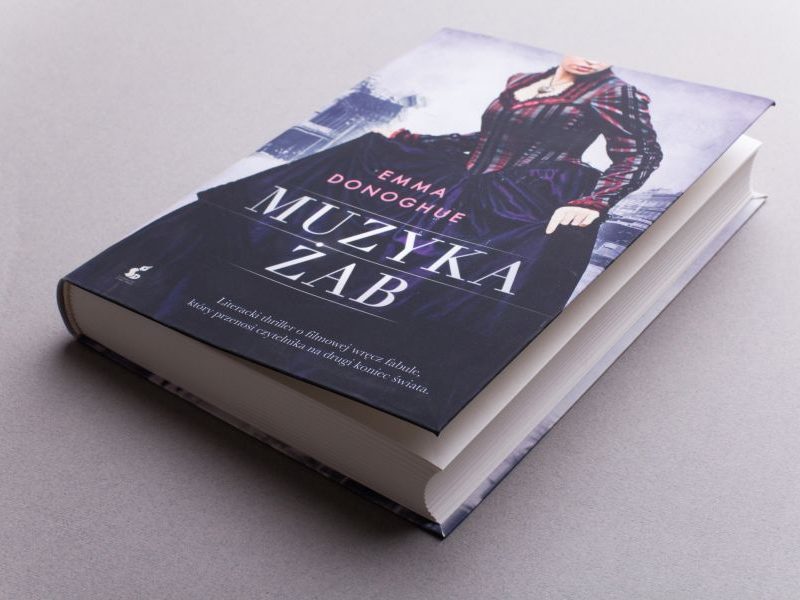

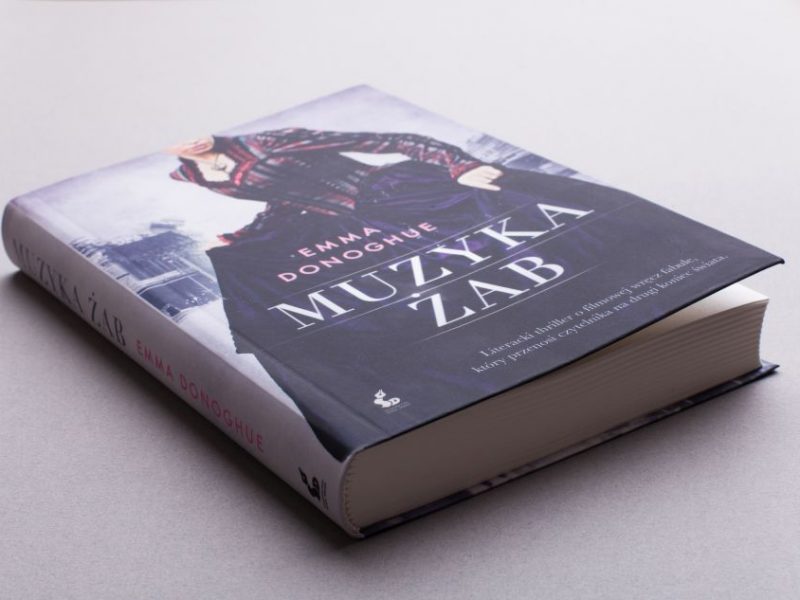

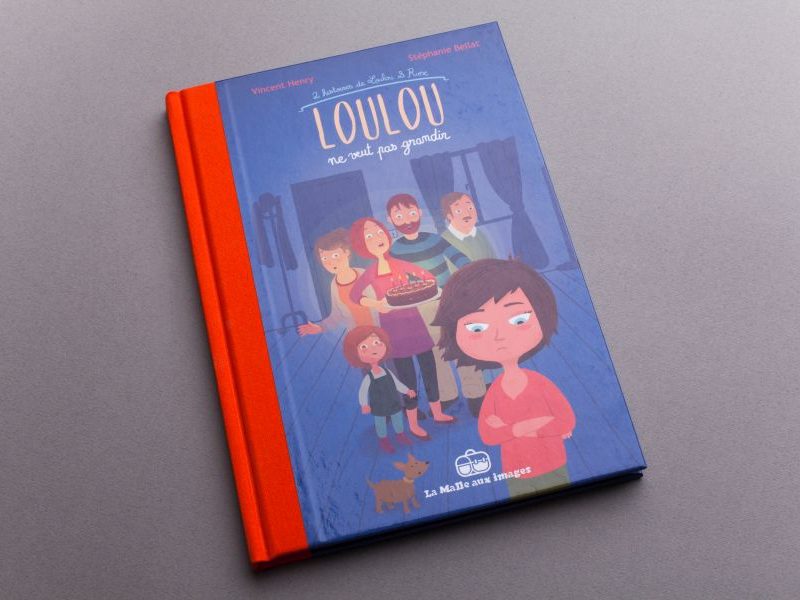

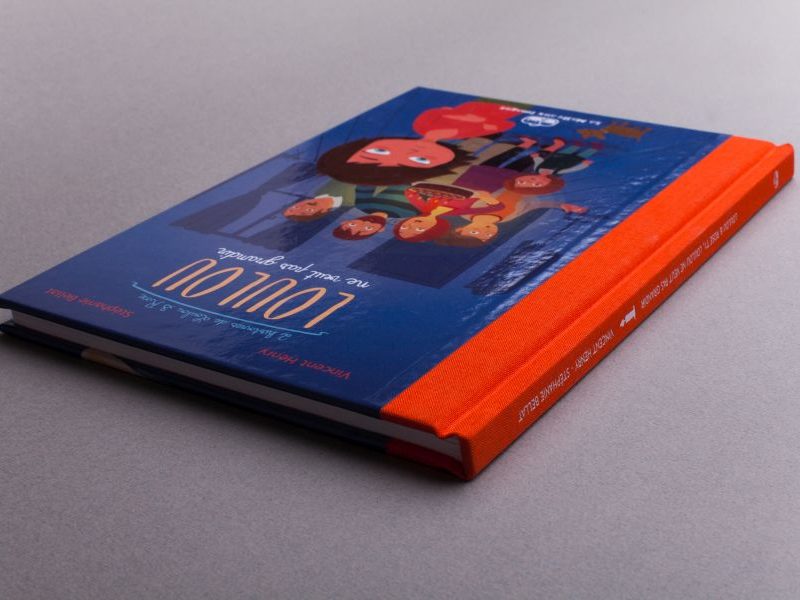

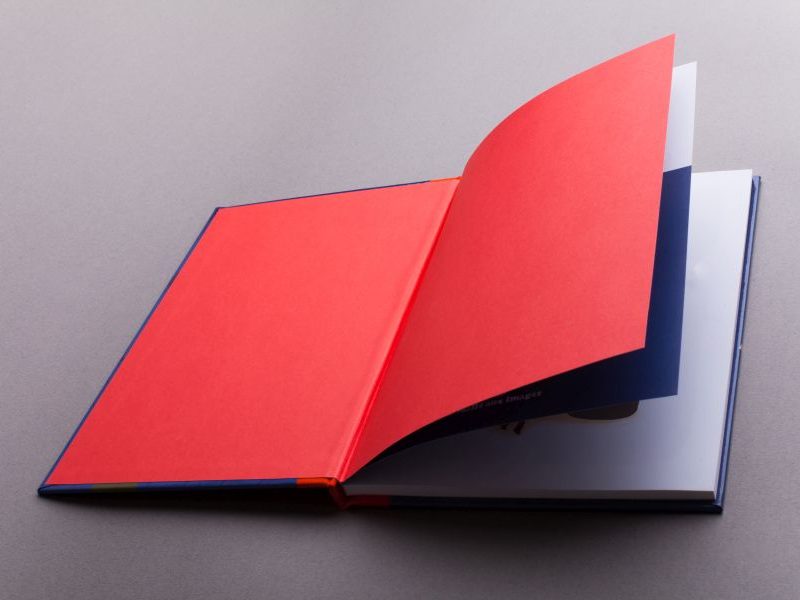

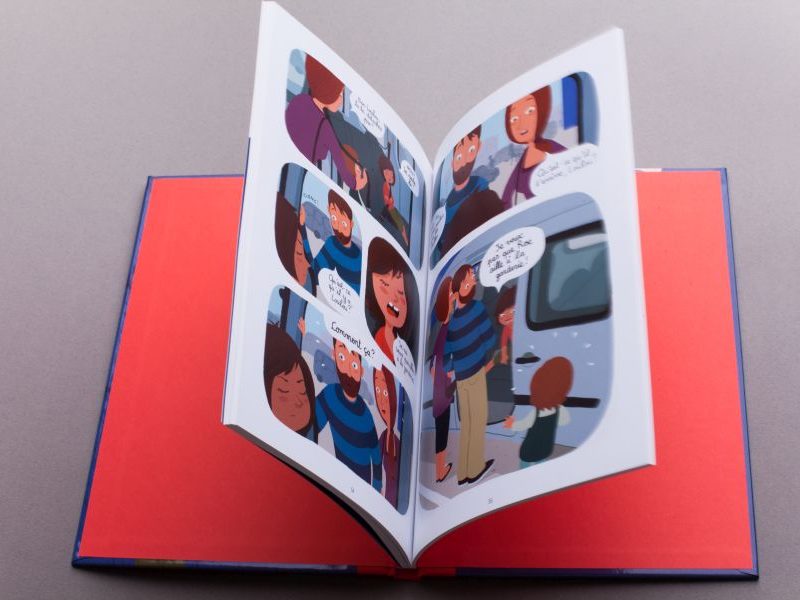

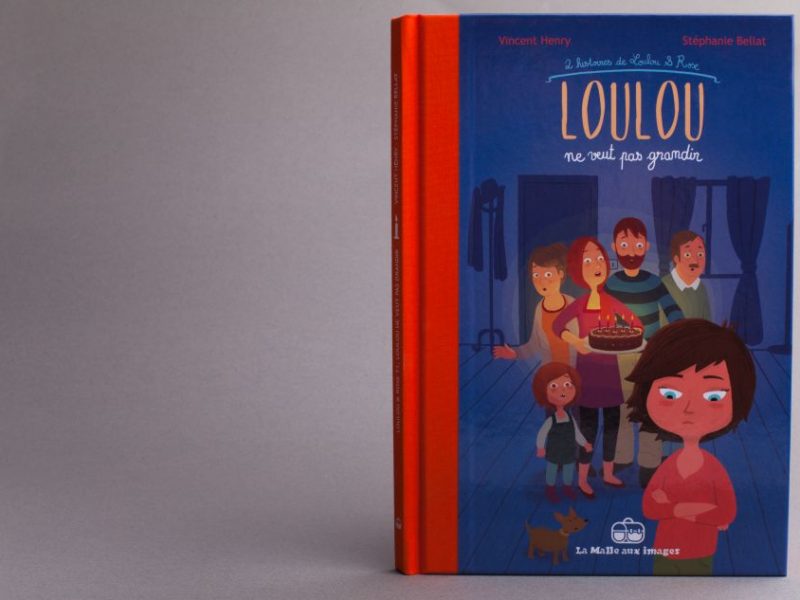

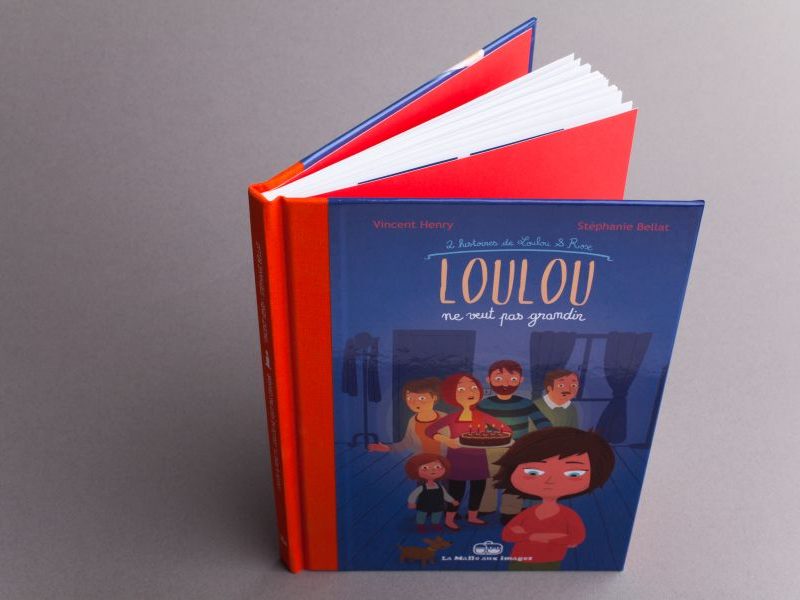

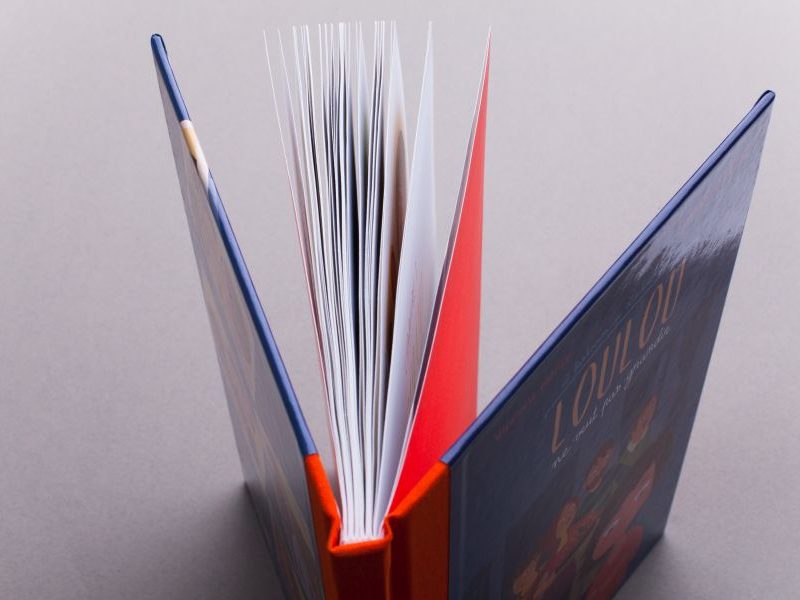

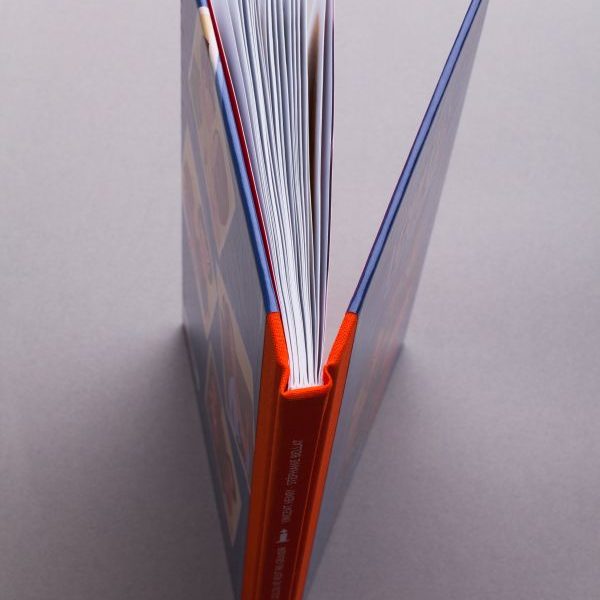

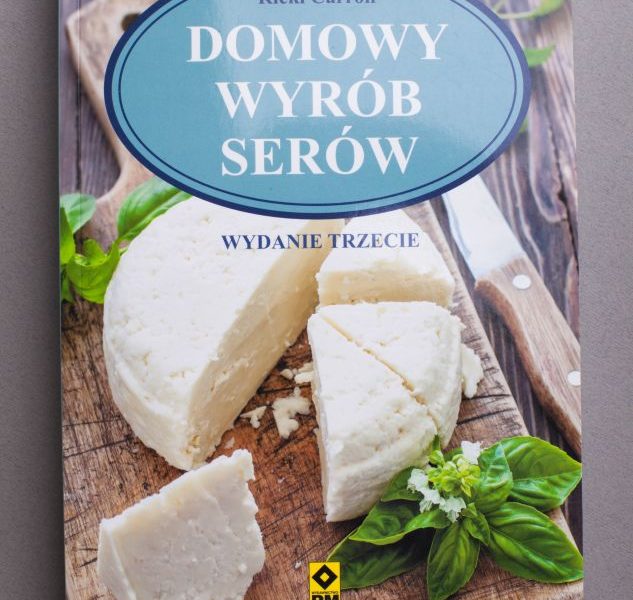

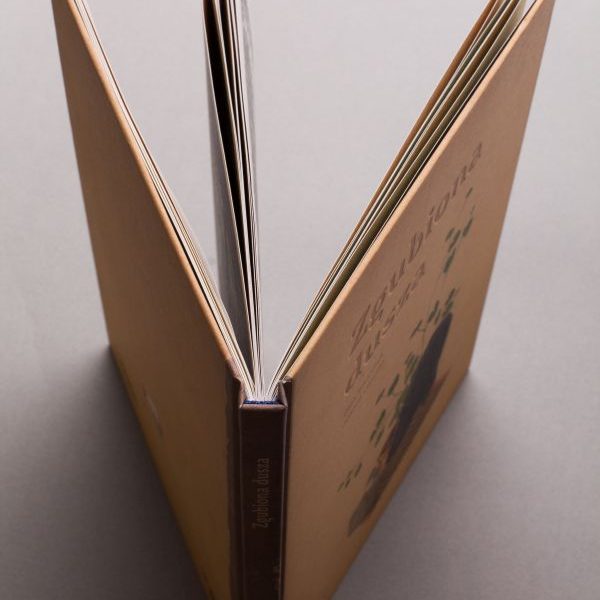

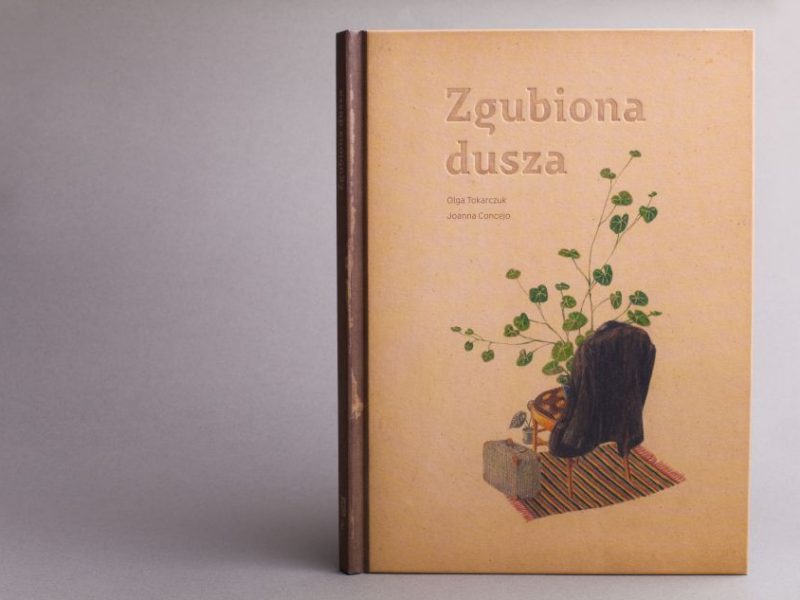

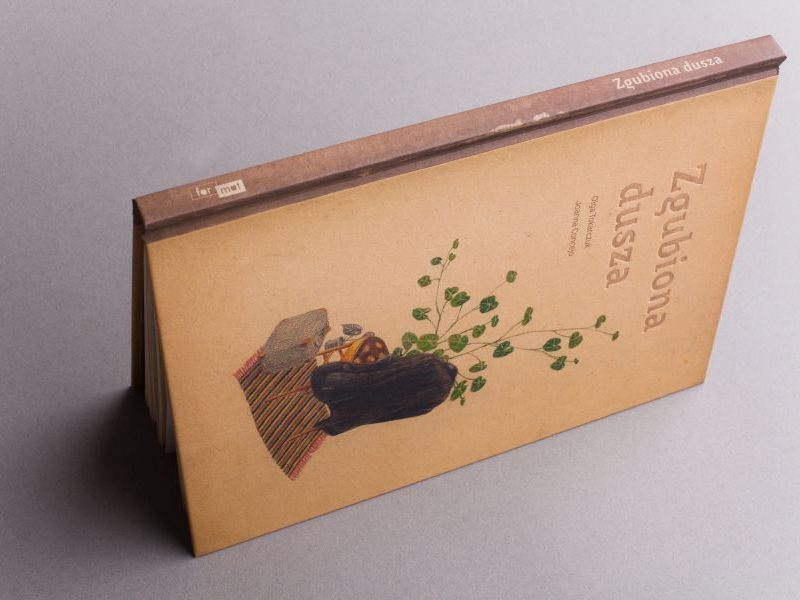

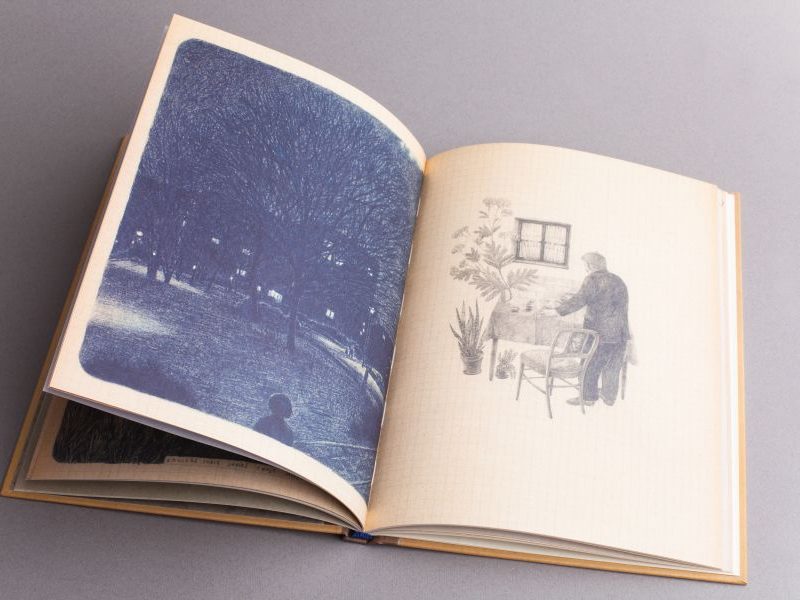

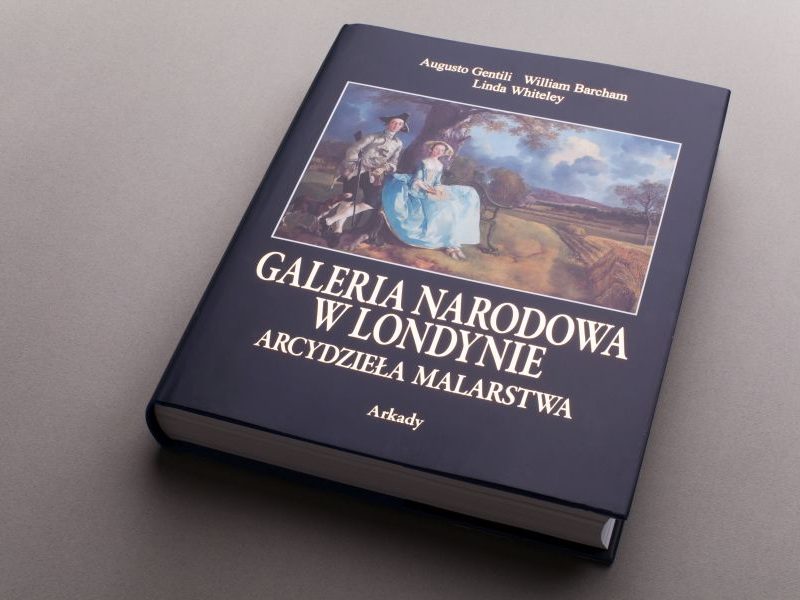

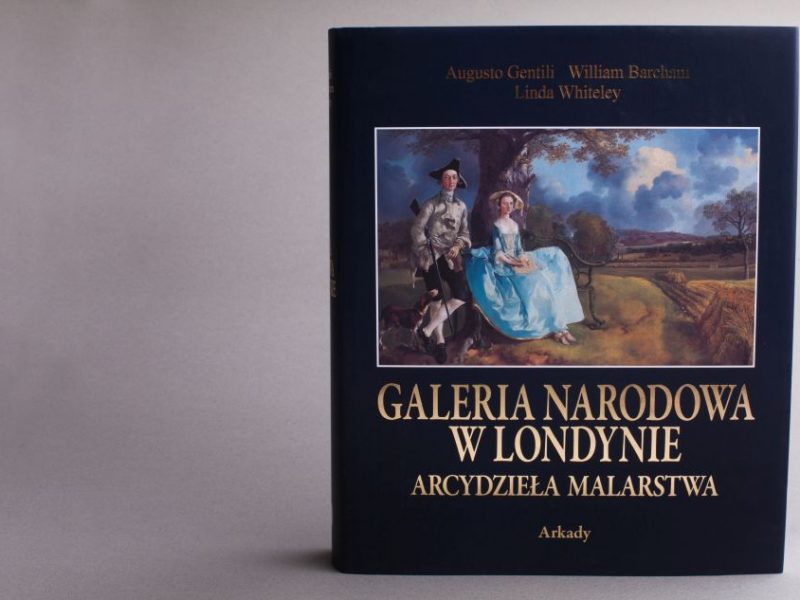

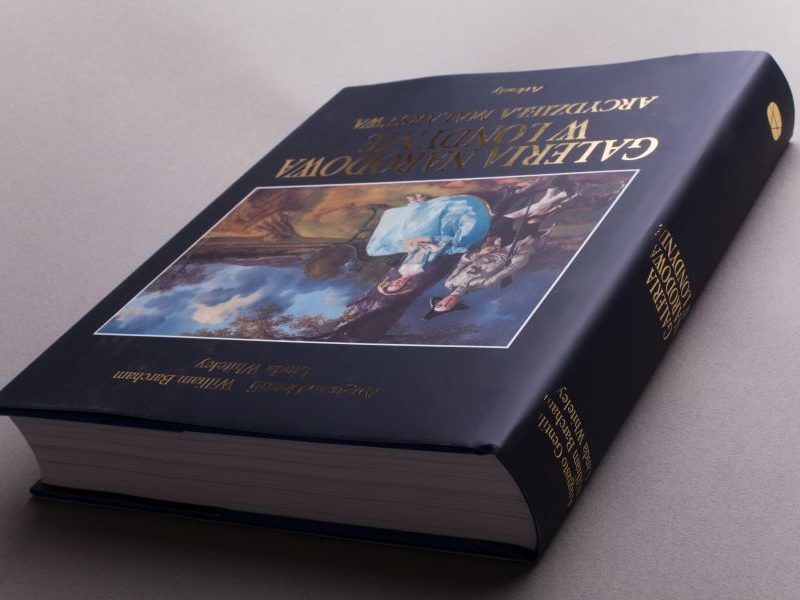

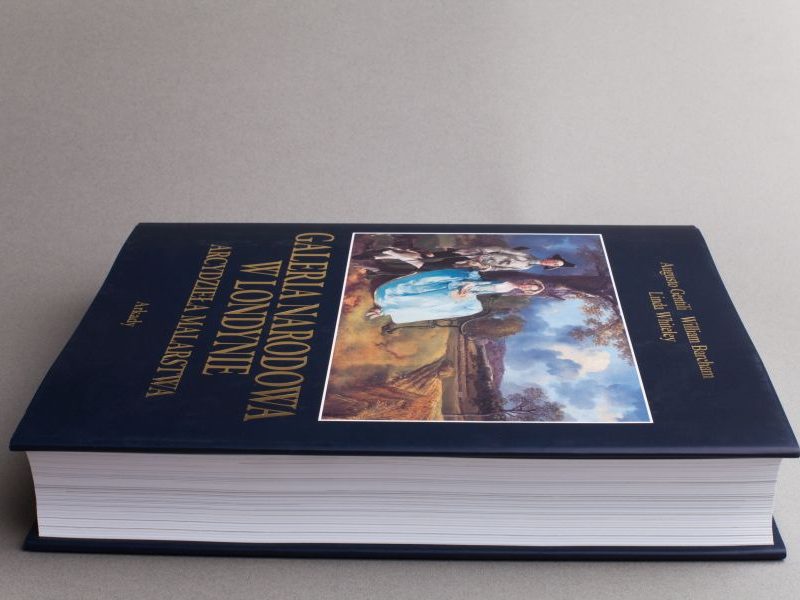

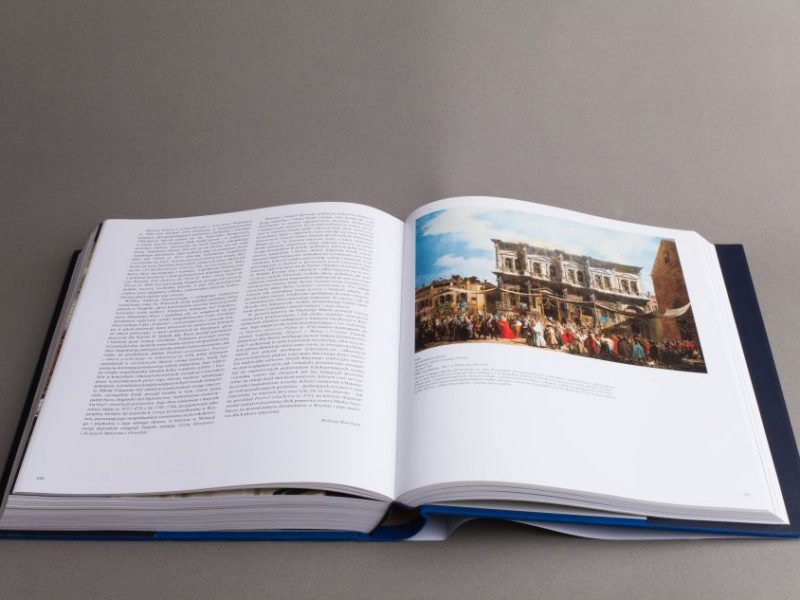

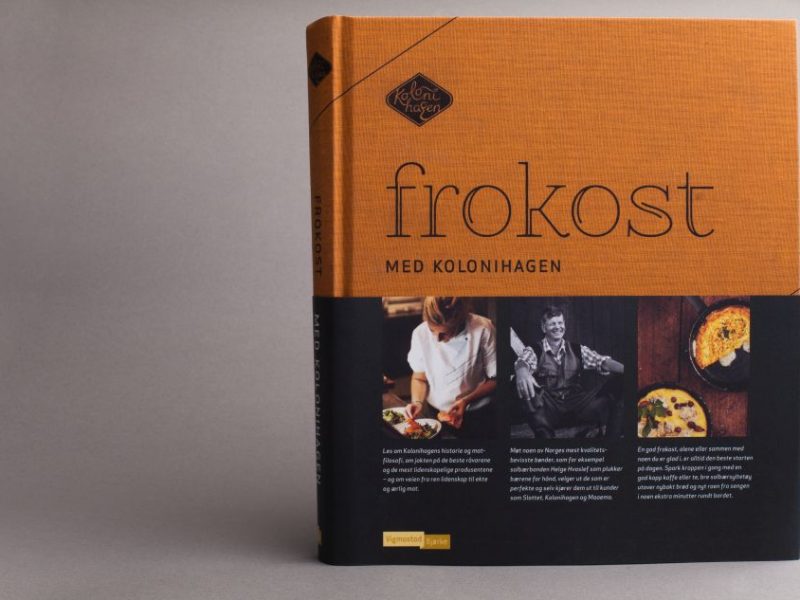

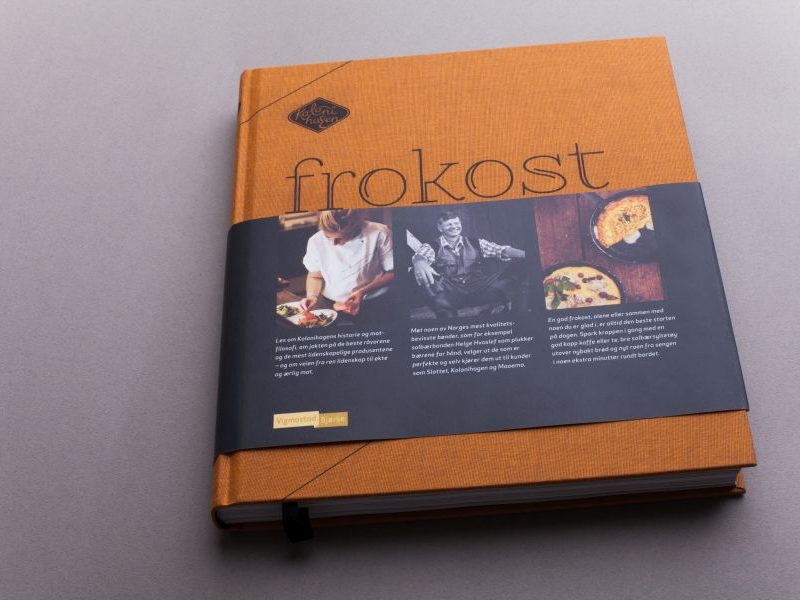

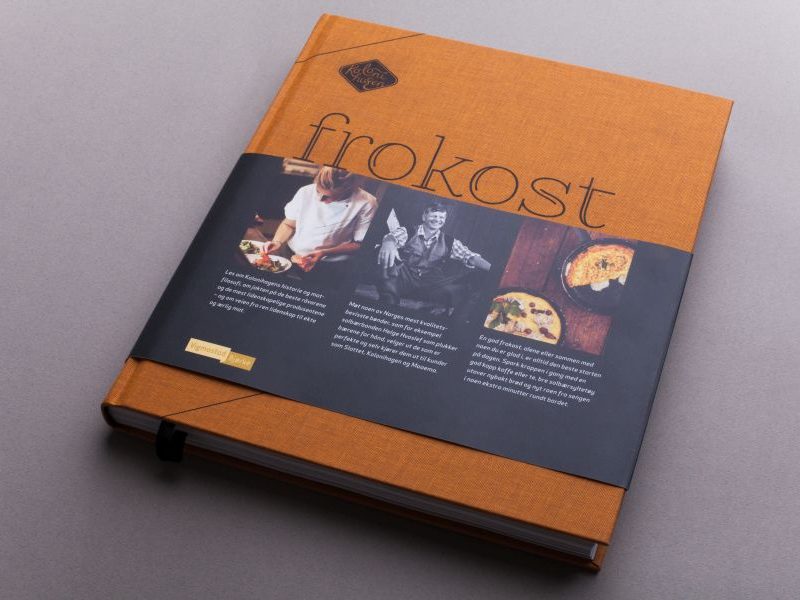

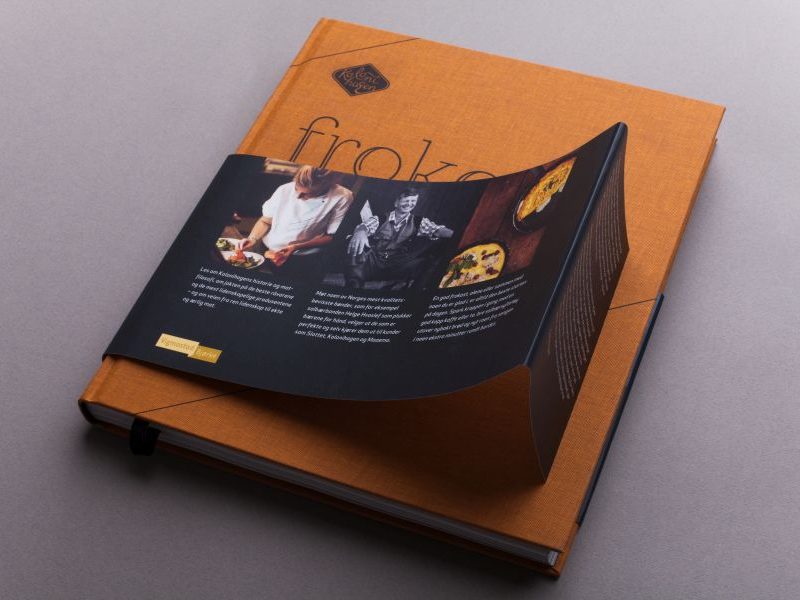

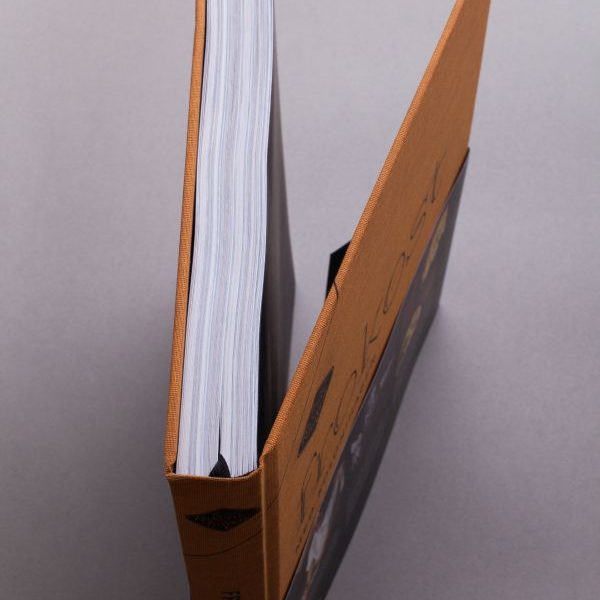

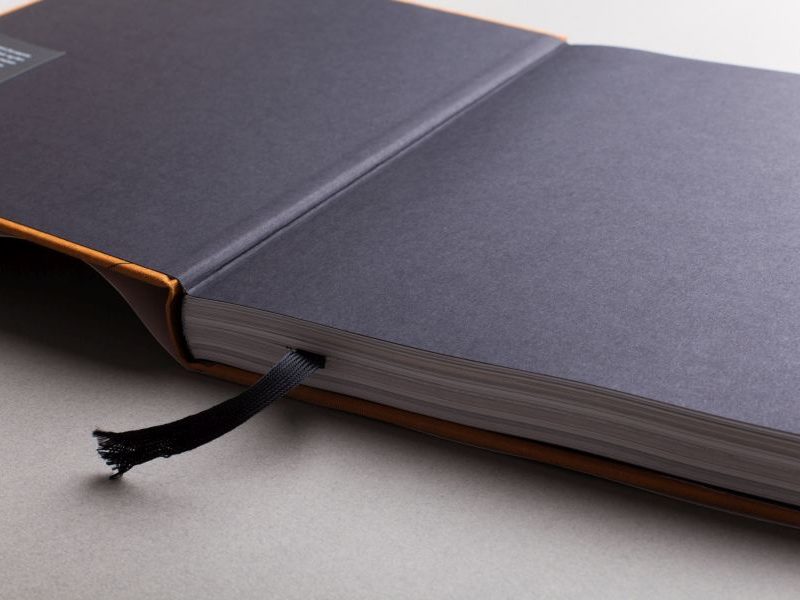

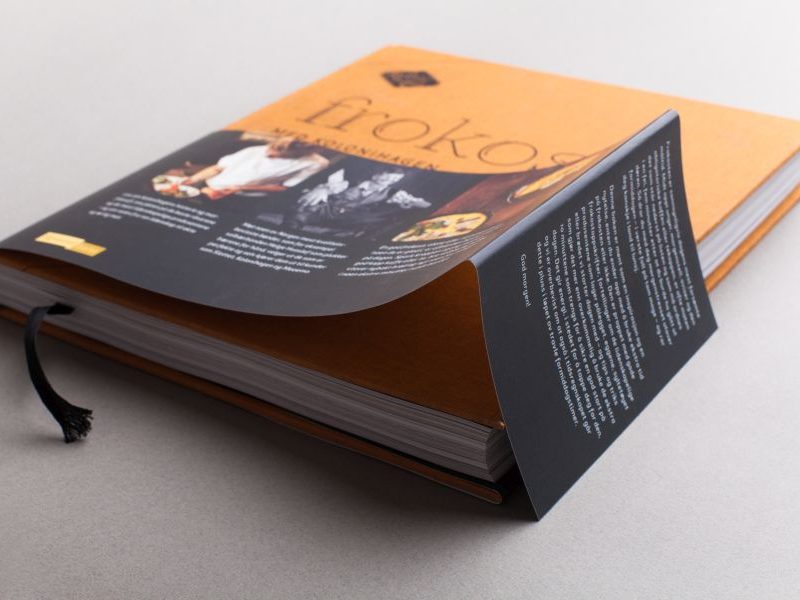

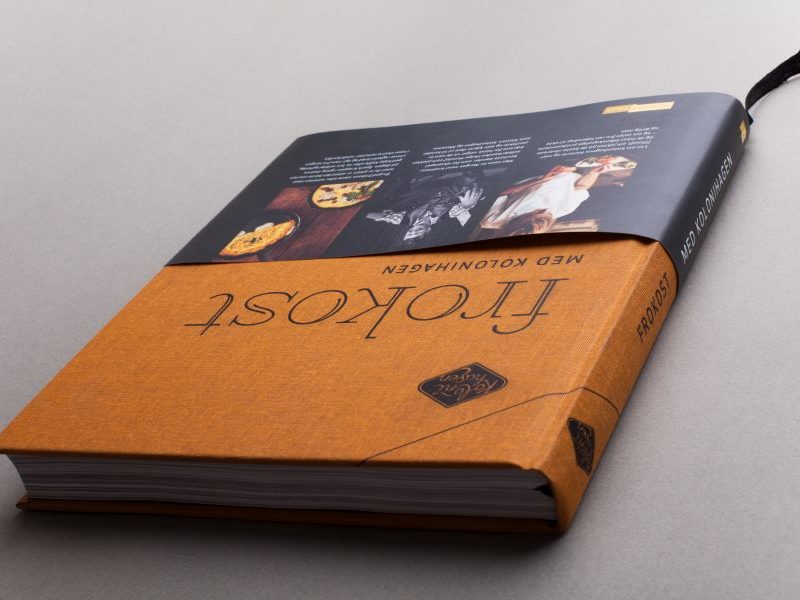

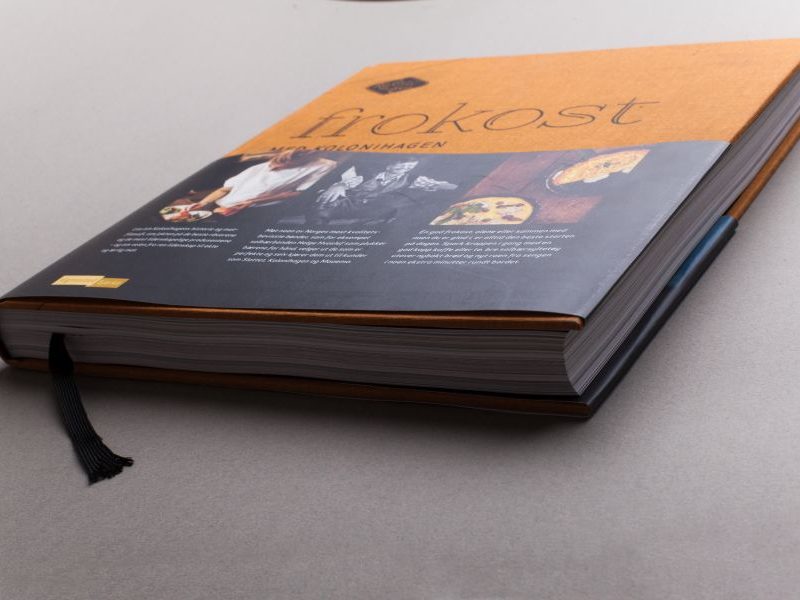

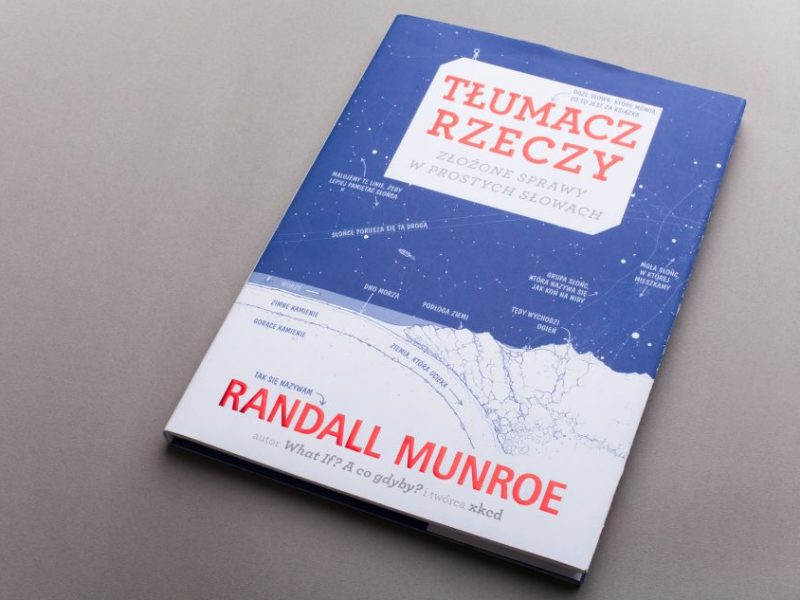

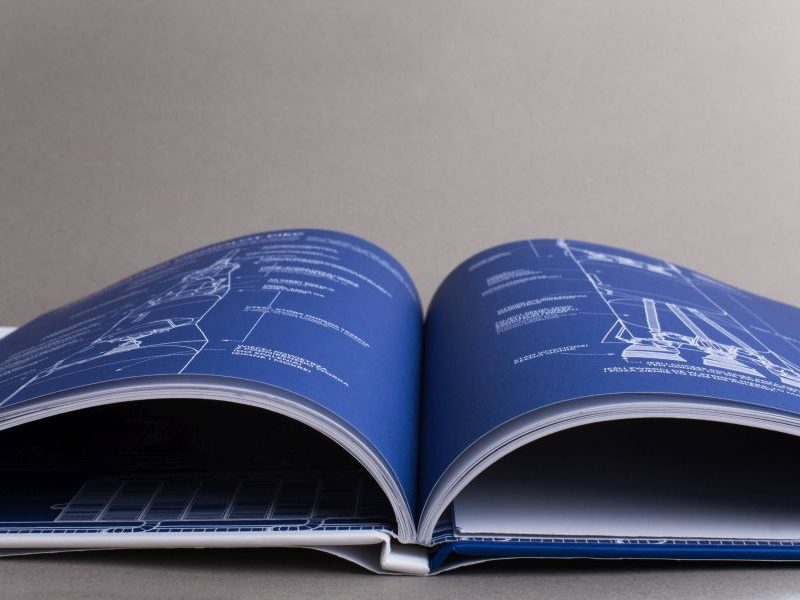

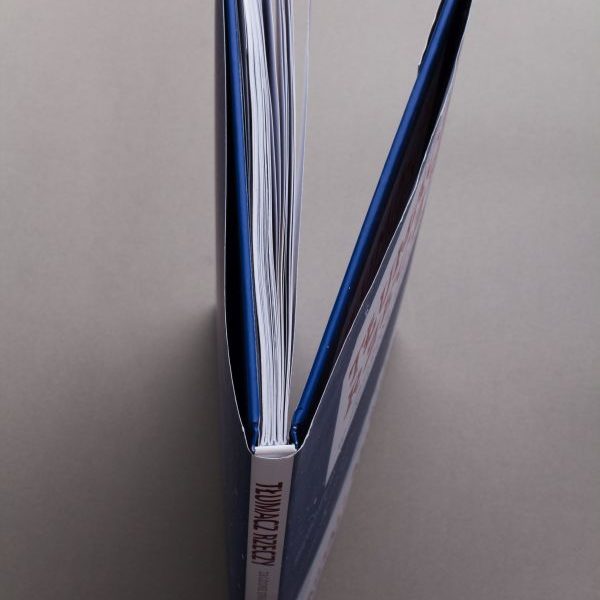

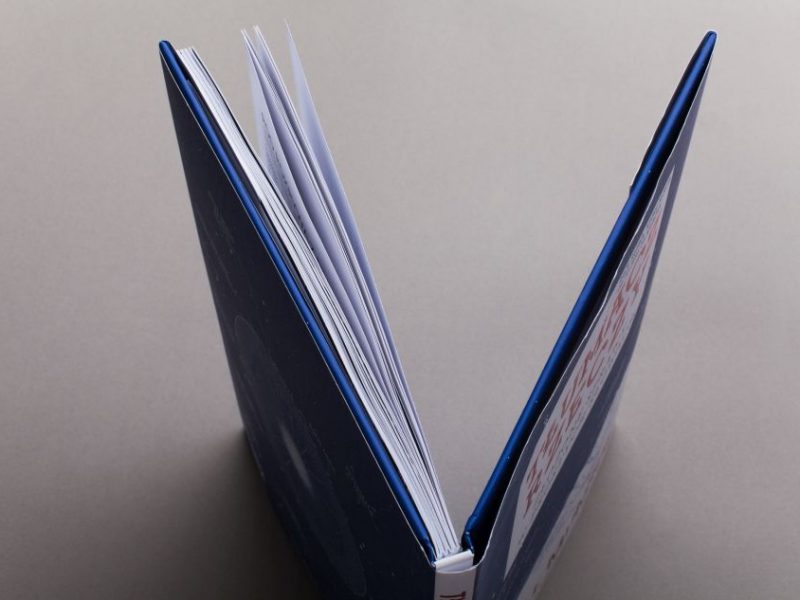

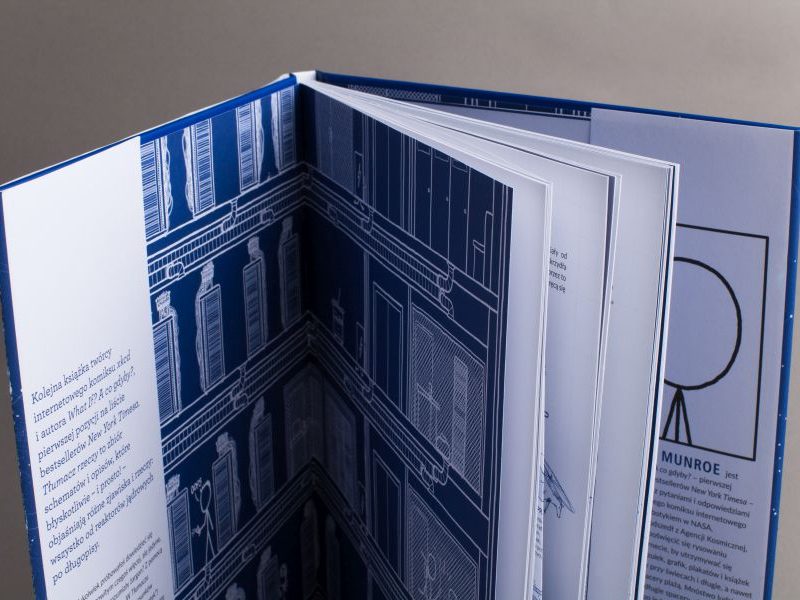

OZGraf S.A. modern bookbindery provides the following bindings:

OZGraf S.A. modern bookbindery provides the following bindings: